vs 1. Principle and Essence: Based on resistance welding, it applies mechanical pressure and high currents through electrodes, utilizing the heat generated by metal contact resistance to melt the weld point and achieve connection. 2....

|

|

vs |  |

|

|

1. Principle and Essence: Based on resistance welding, it applies mechanical pressure and high currents through electrodes, utilizing the heat generated by metal contact resistance to melt the weld point and achieve connection. 2. There is a high likelihood of false welds and bridging, with significant fluctuations in contact resistance (often 50mΩ), and the average weld point tensile strength is typically < 1N. Residual flux leads to poor heat resistance and easy detachment in high-temperature environments. 3. Human error results in a defect rate of 15%, and the yield rate for mass production often falls below 75%. Issues such as wire thinning and insulation layer melting are frequent. |

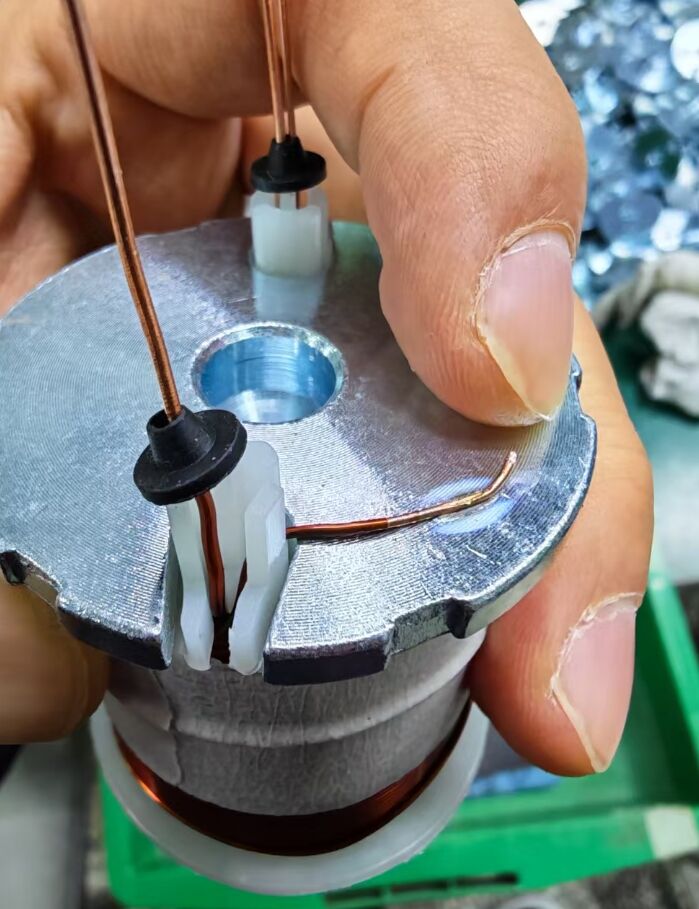

1. Principle and Essence: Centered around micro arc welding or laser welding, employing non-contact energy transmission. By precisely controlling the heating process through high-frequency short pulses, and complemented by visual positioning and intelligent parameter adjustment, micron-level welding is achieved. For example, micro arc spot welding uses a momentary arc to melt the terminals in less than 0.1 seconds, enveloping the wire to form a cohesive molten structure. 2. Contact resistance ≤ 35mΩ, weld point tensile strength ≥ 1.5N, performance variation rate after 1000 cycles of hot and cold cycling ≤ 5%; micro arc welding forms a dense molten structure. 3. Defect recognition rate exceeds 99%, yield rate can reach over 99.7%; parameter standardization ensures batch consistency. |

|||