The starter solenoid serves as a critical electrical switch in your vehicle's starting system, controlling the flow of high-amperage current from the battery to the starter motor. This essential component directly impacts your car's ability to start reliably, making proper maintenance crucial for extending the overall life of your starter system. Understanding how to care for this component can save you from unexpected breakdowns and costly repairs while ensuring your vehicle starts smoothly every time.

Understanding the Role of Starter Solenoids in Vehicle Operation

Primary Functions and Electrical Connections

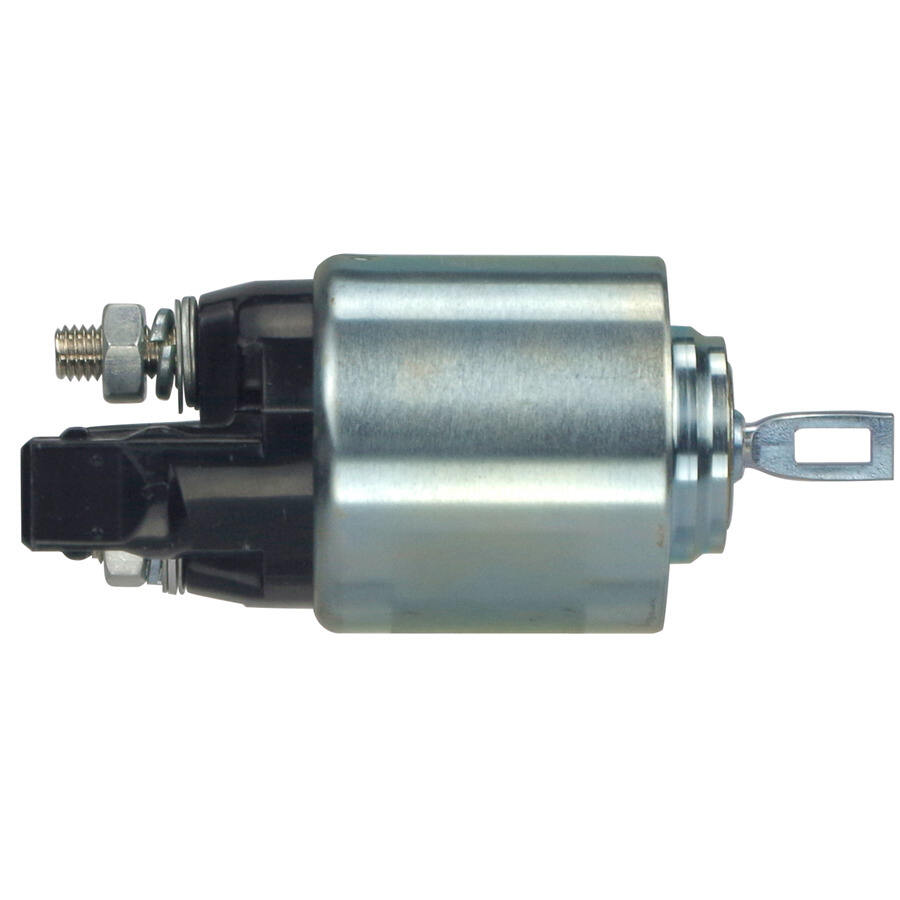

A starter solenoid acts as both an electrical relay and a mechanical actuator within your vehicle's starting circuit. When you turn the ignition key, the solenoid receives a low-current signal from the ignition switch and responds by closing heavy-duty contacts that allow battery power to flow directly to the starter motor. Simultaneously, the solenoid pushes the starter drive gear into engagement with the engine's flywheel ring gear through its mechanical plunger action.

The dual functionality of this component makes it particularly susceptible to both electrical and mechanical wear over time. The electrical contacts inside the solenoid must handle hundreds of amperes during each starting cycle, while the mechanical components must precisely align the starter drive with the flywheel teeth. This demanding operational environment requires regular attention to maintain optimal performance and prevent premature failure.

Common Signs of Starter Solenoid Deterioration

Recognizing early warning signs of starter solenoid problems allows for preventive maintenance before complete failure occurs. One of the most common indicators is a clicking sound when attempting to start the engine, which typically means the solenoid is receiving the ignition signal but failing to properly close the main power contacts. This clicking may occur once per start attempt or repeatedly in rapid succession.

Another telltale sign involves intermittent starting problems where the engine cranks normally on some attempts but fails to engage on others. This inconsistency often indicates worn or corroded solenoid contacts that make unreliable electrical connections. Additionally, if you notice that the starter motor runs continuously even after releasing the ignition key, the solenoid contacts may be welded closed due to excessive arcing or overheating.

Essential Maintenance Procedures for Optimal Performance

Regular Electrical Connection Inspection

Maintaining clean, tight electrical connections represents one of the most important aspects of starter solenoid care. Begin by disconnecting the battery negative terminal before inspecting any electrical components for safety. Remove the protective caps or covers from the solenoid terminals and visually examine all wire connections for signs of corrosion, fraying, or looseness.

Use a wire brush or fine sandpaper to clean any corrosion from terminal posts and cable ends, ensuring bright, clean metal surfaces for optimal electrical contact. Apply a thin layer of dielectric grease to protect these connections from future corrosion caused by moisture and road salt exposure. Tighten all connections to manufacturer specifications using the appropriate tools, being careful not to over-tighten and damage the solenoid housing threads.

Voltage Drop Testing and Circuit Analysis

Periodic voltage drop testing helps identify developing problems within the starter solenoid circuit before they cause complete failure. Using a digital multimeter, measure the voltage drop across the solenoid during actual starting operations to ensure proper electrical efficiency. A healthy starter solenoid should exhibit minimal voltage drop, typically less than 0.5 volts across its main power contacts during cranking.

Test the control circuit voltage as well, verifying that the solenoid receives adequate signal voltage from the ignition switch during start attempts. Low control voltage can cause weak solenoid engagement, leading to poor contact closure and excessive electrical resistance. Document these measurements and compare them to manufacturer specifications to identify trends that may indicate gradual deterioration requiring attention.

Environmental Factors Affecting Starter Solenoid Longevity

Temperature Extremes and Thermal Protection

Temperature fluctuations significantly impact starter solenoid performance and lifespan, particularly in regions experiencing extreme seasonal variations. High temperatures can cause solenoid coil insulation to break down over time, while excessive heat buildup during operation may weld the internal contacts together. Conversely, extremely cold conditions increase the electrical resistance within the solenoid windings and can cause mechanical components to operate sluggishly.

Consider installing heat shields or thermal barriers around the starter solenoid if your vehicle operates in consistently high-temperature environments such as commercial applications or hot climates. Ensure adequate ventilation around the solenoid housing to promote heat dissipation during normal operation. Regular inspection of the solenoid mounting location can help identify heat-related damage before it progresses to component failure.

Moisture Protection and Corrosion Prevention

Moisture infiltration poses a serious threat to starter solenoid integrity, particularly in vehicles exposed to harsh weather conditions or frequent water crossings. Water can cause internal corrosion of electrical contacts and may lead to short circuits or ground faults within the solenoid assembly. The combination of moisture and road salt creates an especially corrosive environment that accelerates component deterioration.

Regularly inspect the solenoid housing for cracks or damaged seals that might allow moisture penetration. Replace any compromised gaskets or O-rings immediately to maintain proper environmental protection. Consider applying appropriate sealants to electrical connections and using waterproof connector boots where available to provide additional moisture barriers in challenging operating environments.

Advanced Troubleshooting and Performance Optimization

Load Testing and Current Draw Analysis

Professional load testing provides valuable insights into starter solenoid condition and overall system health that simple voltage measurements cannot reveal. A proper load test evaluates the solenoid's ability to maintain stable voltage under actual cranking loads while monitoring current draw characteristics throughout the starting cycle. This comprehensive analysis helps identify developing problems such as increased internal resistance or mechanical binding.

Monitor the solenoid's current draw patterns during testing to identify abnormal characteristics that may indicate internal wear or damage. A healthy starter solenoid should engage cleanly with consistent current draw and maintain stable operation throughout the cranking cycle. Erratic current patterns, excessive draw, or delayed engagement responses suggest internal problems requiring immediate attention or replacement.

Preventive Replacement Strategies

Implementing a proactive replacement schedule for starter solenoids can prevent unexpected failures and reduce overall maintenance costs. Consider the operating environment, usage patterns, and manufacturer recommendations when establishing replacement intervals. Vehicles operating in severe conditions such as extreme temperatures, high dust environments, or frequent start-stop cycles may require more frequent solenoid replacement.

Keep detailed maintenance records documenting solenoid performance trends, test results, and any observed changes in operation. This historical data helps predict when replacement becomes necessary and allows for planned maintenance scheduling rather than emergency repairs. Quality replacement components specifically designed for your vehicle's requirements ensure optimal performance and longevity while maintaining proper system integration.

FAQ

How often should I inspect my starter solenoid for maintenance purposes

Most automotive experts recommend inspecting starter solenoid connections and operation during regular maintenance intervals, typically every 12 months or 15,000 miles. However, vehicles operating in harsh conditions or commercial applications may benefit from more frequent inspections every 6-8 months. Regular visual inspection of connections and listening for unusual sounds during starting can help identify developing problems early.

What tools do I need for basic starter solenoid maintenance

Essential tools for starter solenoid maintenance include a digital multimeter for electrical testing, wire brushes for cleaning connections, dielectric grease for corrosion protection, and basic hand tools for removing and tightening connections. A battery load tester can provide more comprehensive analysis, while thermal imaging equipment helps identify heat-related problems in professional applications.

Can I replace a starter solenoid myself or should I seek professional help

Starter solenoid replacement difficulty varies significantly depending on vehicle design and component accessibility. Simple bolt-on solenoids mounted externally can often be replaced by mechanically inclined individuals with basic tools and safety precautions. However, solenoids integrated into starter motor assemblies or located in difficult-to-access positions typically require professional installation to ensure proper alignment and electrical connections.

How long should a properly maintained starter solenoid last in normal conditions

A well-maintained starter solenoid operating under normal conditions typically provides reliable service for 100,000 to 150,000 miles or 7-10 years. Factors such as climate, driving patterns, and maintenance quality significantly influence actual lifespan. Vehicles with frequent start-stop cycles or those operating in extreme temperatures may experience shorter solenoid life, while highway-driven vehicles in moderate climates often exceed typical replacement intervals.