Understanding the warning signs of starter solenoid malfunction can save drivers from unexpected breakdowns and costly repairs. The starter solenoid serves as a critical electrical component that bridges the gap between your ignition system and the starter motor, making it essential for reliable vehicle operation. When this small but vital component begins to fail, it typically exhibits distinct symptoms that alert experienced drivers to potential problems before complete failure occurs.

Modern automotive electrical systems rely heavily on precise component functionality to ensure smooth engine startup sequences. The starter solenoid acts as an electromagnetic switch that controls high-amperage current flow from the battery to the starter motor. Without proper solenoid operation, even vehicles with fully charged batteries and functional starter motors will fail to engage properly during ignition attempts.

Understanding Starter Solenoid Function and Operation

Electrical Circuit Integration

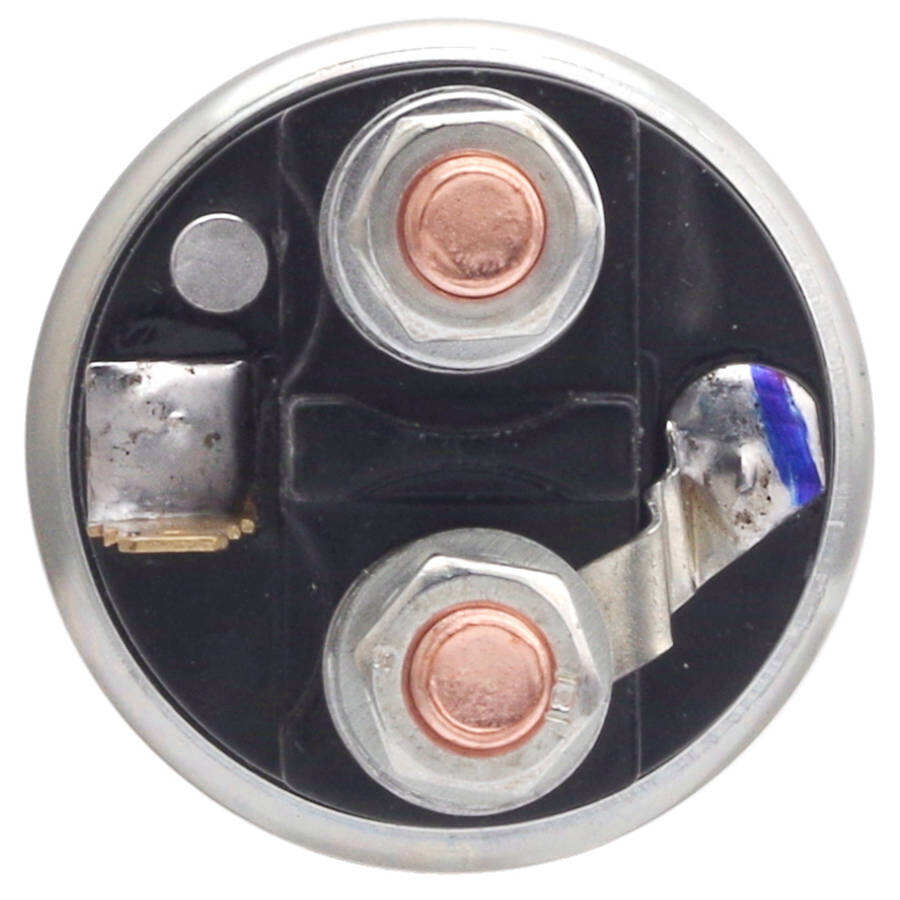

The starter solenoid operates within a complex electrical circuit that includes the ignition switch, battery, starter motor, and various safety interlocks. When the ignition key turns to the start position, a small electrical current activates the solenoid coil, creating an electromagnetic field that pulls the solenoid plunger inward. This action closes heavy-duty contacts that allow full battery voltage and amperage to flow directly to the starter motor.

Professional automotive technicians recognize that solenoid failure often stems from contact wear, coil degradation, or mechanical binding within the plunger assembly. Heat cycling from repeated engine starts, combined with exposure to engine bay temperature fluctuations, gradually degrades internal components over time. Understanding this operational principle helps drivers recognize why certain failure symptoms manifest during different stages of component deterioration.

Component Interaction Dynamics

The relationship between starter solenoid performance and overall starting system efficiency becomes apparent when examining voltage drop patterns across the circuit. Healthy solenoids maintain consistent voltage transfer with minimal resistance, while failing units exhibit increasing resistance that reduces available power to the starter motor. This degradation typically occurs gradually, providing observant drivers with early warning signs before complete system failure.

Advanced diagnostic equipment can measure precise voltage characteristics across solenoid terminals, but drivers can often detect performance issues through careful observation of starting behavior changes. Subtle variations in cranking speed, unusual electrical noises, or intermittent starting difficulties frequently indicate developing solenoid problems that warrant professional inspection and potential replacement.

Primary Symptoms of Starter Solenoid Failure

Clicking Sounds During Engine Start Attempts

One of the most recognizable indicators of starter solenoid malfunction involves repetitive clicking sounds that occur when turning the ignition key to the start position. These clicks represent the solenoid attempting to engage but failing to maintain proper contact closure due to worn or pitted internal components. The rapid cycling creates an audible clicking pattern that experienced mechanics immediately associate with solenoid-related starting problems.

The clicking phenomenon typically begins as occasional occurrences during cold weather or after extended parking periods, then progressively becomes more frequent as component degradation continues. Drivers should distinguish between single clicks that might indicate other electrical issues and rapid-fire clicking sequences that specifically point toward starter solenoid problems requiring immediate attention.

Intermittent Starting Issues

Inconsistent engine starting represents another primary symptom of developing starter solenoid failure that confuses many vehicle owners. The engine may start normally during some attempts while completely failing to respond during others, creating unpredictable transportation reliability. This intermittent behavior occurs when solenoid contacts make partial connections that occasionally allow sufficient current flow for starter motor operation.

Temperature variations significantly influence intermittent starting symptoms, with many drivers reporting improved performance during cooler weather and increased problems during hot summer conditions. The thermal expansion of worn solenoid components can prevent proper contact engagement, while cooler temperatures may temporarily restore adequate electrical continuity for successful engine starts.

Advanced Diagnostic Techniques and Testing Methods

Voltage Drop Testing Procedures

Professional mechanics employ specialized voltage drop testing to accurately assess starter solenoid condition beyond simple visual inspection or audible symptom evaluation. This testing involves measuring voltage differences across solenoid terminals during actual starting attempts, providing quantitative data about internal resistance and contact effectiveness. Healthy solenoids typically exhibit voltage drops below 0.5 volts, while failing units may show readings exceeding 1.0 volt during operation.

Voltage drop testing requires proper safety procedures and appropriate test equipment to avoid electrical hazards during live circuit evaluation. Technicians connect digital multimeters across specific solenoid terminals while observing readings during cranking cycles, documenting performance variations that indicate deteriorating component condition requiring replacement intervention.

Circuit Continuity Verification

Comprehensive starter solenoid evaluation includes circuit continuity testing that examines both the control circuit and high-amperage power circuit functionality. Control circuit testing verifies proper voltage delivery from the ignition switch through safety interlocks to the solenoid activation coil. Power circuit testing confirms adequate current-carrying capacity through the main solenoid contacts during starter motor engagement sequences.

Advanced diagnostic protocols often reveal intermittent circuit problems that escape detection during basic testing procedures. Technicians may perform extended testing cycles that simulate various operating conditions, including temperature variations and electrical load changes that can expose marginal solenoid performance before complete failure occurs.

Prevention Strategies and Maintenance Recommendations

Regular Electrical System Inspection

Proactive maintenance approaches can significantly extend starter solenoid service life while preventing unexpected failure situations that leave drivers stranded. Regular inspection of battery terminals, cable connections, and related electrical components helps maintain optimal circuit conditions that reduce solenoid stress during normal operation. Clean, tight connections ensure efficient current flow that prevents excessive heat generation within solenoid contacts.

Seasonal maintenance schedules should include verification of starting system performance, particularly before extreme weather periods that challenge electrical component reliability. Professional technicians can perform preventive testing that identifies developing problems while components remain serviceable, allowing scheduled replacement during convenient maintenance intervals rather than emergency repair situations.

Environmental Protection Measures

Protecting starter solenoid components from environmental contamination extends operational lifespan while maintaining consistent performance characteristics. Engine bay cleanliness reduces corrosive exposure that can accelerate contact deterioration and compromise electrical connections over time. Regular cleaning of solenoid mounting areas and associated wiring harnesses prevents moisture accumulation that contributes to premature component failure.

Drivers operating vehicles in harsh environmental conditions should consider more frequent inspection intervals and potential protective measures such as dielectric grease application on electrical connections. These preventive steps help maintain starter solenoid reliability even under challenging operating conditions that typically accelerate component wear patterns.

FAQ

How long does a typical starter solenoid last before requiring replacement

Most starter solenoids provide reliable service for approximately 100,000 to 150,000 miles under normal driving conditions, though this lifespan varies significantly based on climate, driving patterns, and maintenance quality. Vehicles subjected to frequent short trips, extreme temperatures, or poor electrical system maintenance may experience solenoid failure much earlier than average expectations.

Can a failing starter solenoid damage other electrical components

Yes, a deteriorating starter solenoid can cause voltage spikes and irregular current flow patterns that potentially damage sensitive electronic components throughout the vehicle electrical system. Additionally, excessive heat generation from poor solenoid contacts can affect nearby wiring harnesses and related starter system components, leading to cascading failure scenarios.

What tools are required for starter solenoid replacement

Basic starter solenoid replacement typically requires standard hand tools including wrenches, screwdrivers, and electrical pliers, though specific tool requirements vary by vehicle design and solenoid mounting configuration. Some installations may require specialized tools for accessing solenoids mounted in confined engine bay locations or integrated within starter motor assemblies.

Are there warning signs that appear before complete starter solenoid failure

Most starter solenoids exhibit progressive failure symptoms including increasingly frequent clicking sounds, slower cranking speeds, and intermittent starting difficulties that typically develop over several weeks or months before complete failure occurs. Observant drivers who recognize these early warning signs can schedule convenient replacement before experiencing complete starting system failure.