The starter switch, as a key command component of the vehicle's starting system, its reliability directly affects the vehicle's starting performance and the user experience. To ensure that the starter switch can stably and accurately execute the "on" and "off" commands throughout the vehicle's entire life cycle, we must conduct extremely rigorous durability tests on it in a laboratory environment.

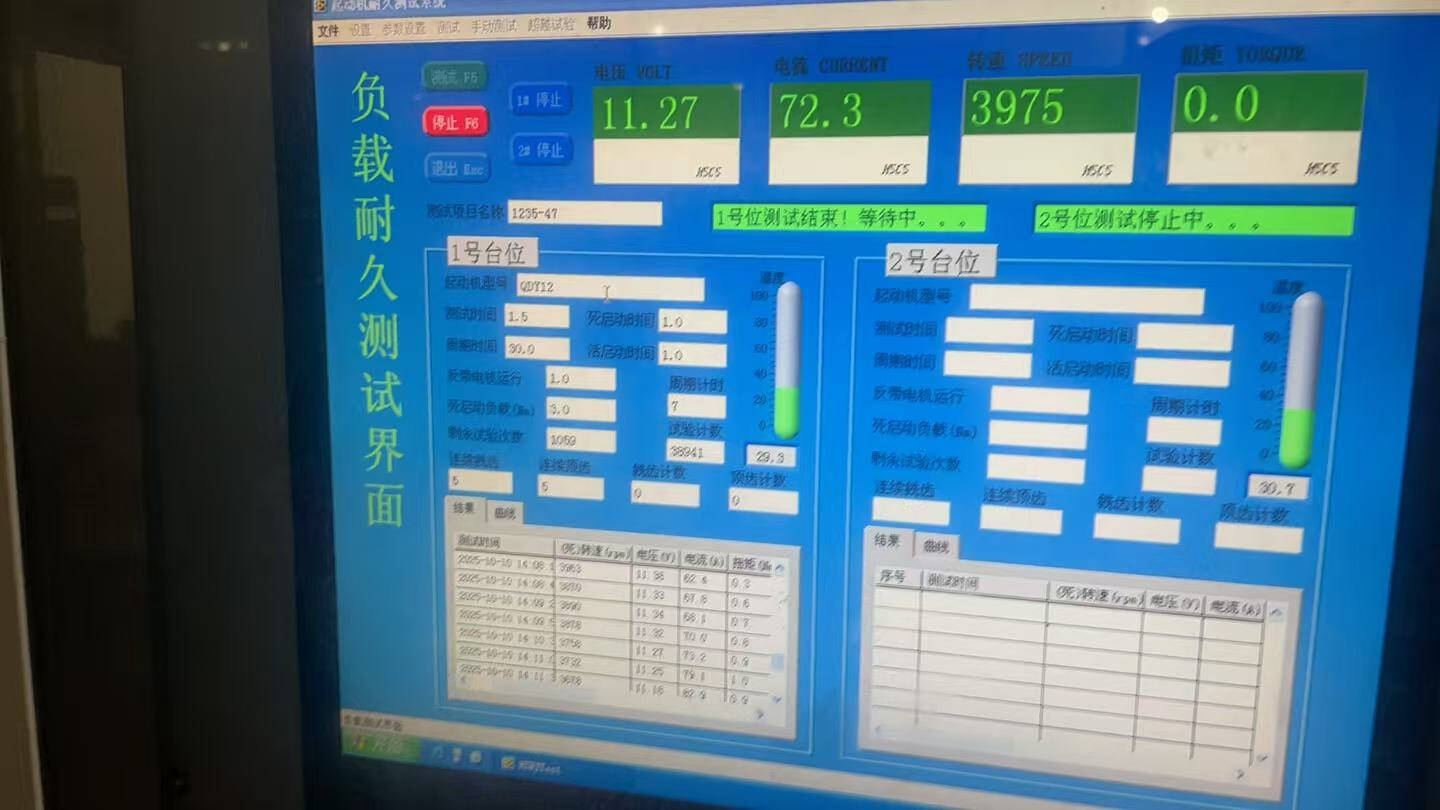

The core of this test lies in simulating the operation process of the switch under real usage scenarios at high frequency and high intensity through dedicated automated testing equipment. During the testing process, the equipment will repeatedly and cyclically operate the switch with precise rhythm and force - to connect the power supply and simulate the load state of the starter driving the engine. Then disconnect and simulate the reset after the engine starts successfully. Each cycle is equivalent to a real vehicle start.

Throughout the entire testing process, we not only focus on whether the switch can meet the "number" requirement of tens of thousands or even hundreds of thousands of cycles, but also attach great importance to its "quality" performance in long-term use. Specifically, it includes the following aspects:

Stability of electrical performance: Pay attention to whether the contact resistance remains at a low and stable level all the time, and whether there is any momentary disconnection or unstable signal.

The durability of the mechanical structure: Check whether the feel of the buttons or knobs remains consistent all the time, and whether the internal springs and contacts have deformed or worn out due to long-term use.

Material resistance and temperature rise: When a large current is passed through for a long time, whether the temperature rise of the switch itself is controlled within a safe range, and whether the shell material will age or crack due to repeated use.

Ultimately, the purpose of the durability test for auto starter solenoid is to exceed the limits of daily use and expose potential design or manufacturing defects in advance. It is like a strict quality inspector, ensuring that every switch leaving the production line can calmly withstand countless start-up tests in any harsh environment, bringing the driver the reliable confidence of "ready to start at any moment".