VS 1. Quality entirely depends on production stability, and defective products reach the end users, resulting in extremely high external loss costs. 2. No quality traceability capability, leading to recurring similar issues. 1. Intercept ...

|

VS |  |

|

1. Quality entirely depends on production stability, and defective products reach the end users, resulting in extremely high external loss costs. 2. No quality traceability capability, leading to recurring similar issues. |

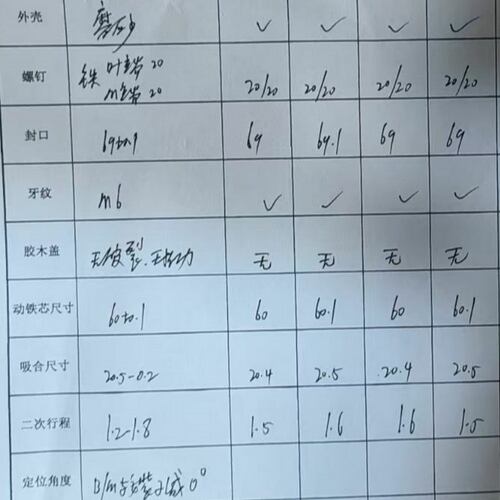

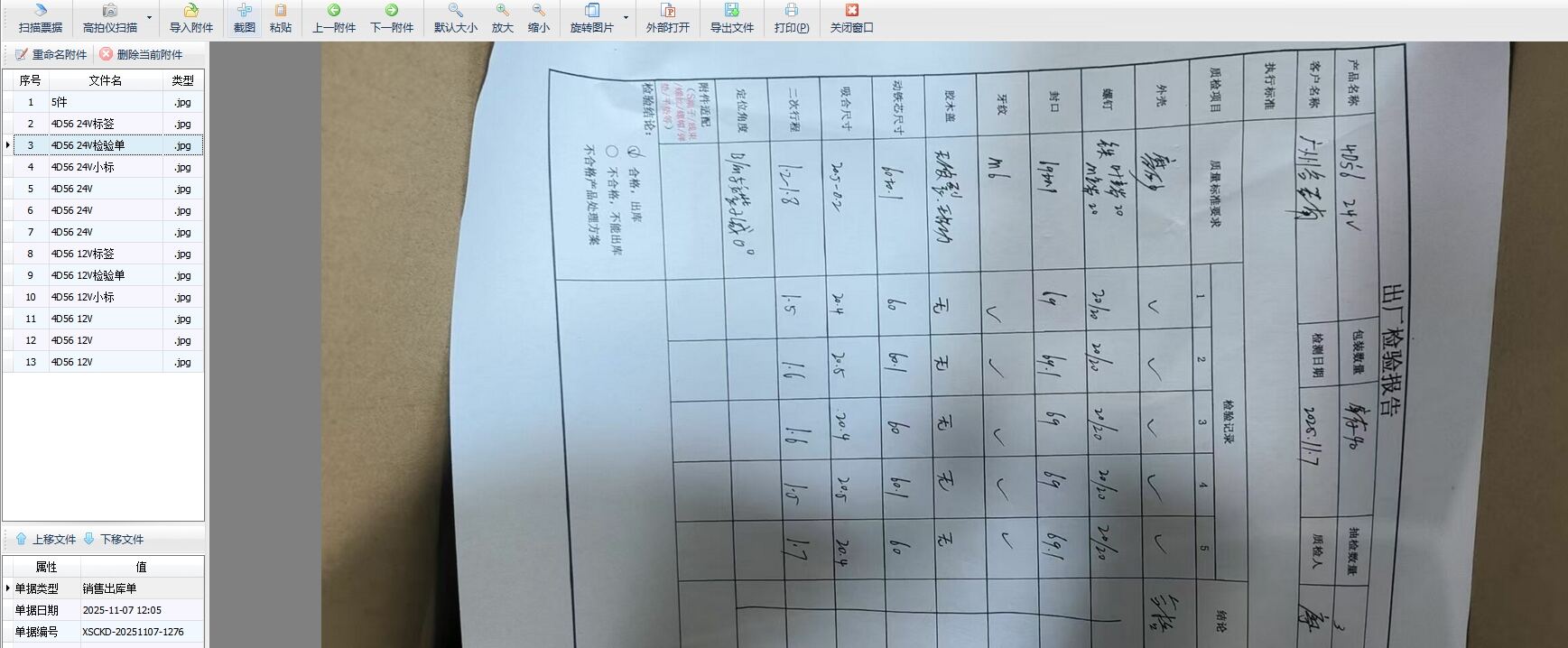

1. Intercept over 90% of obvious defective products during the inspection process, and use SPC (Statistical Process Control) to provide early warnings for hidden quality issues. 2. Build a closed-loop traceability system linking 'inspection data - product batches - user feedback.' 3. Detailed packaging images can serve as proof of quality. |