solenoid switch in starter motor manufacturer

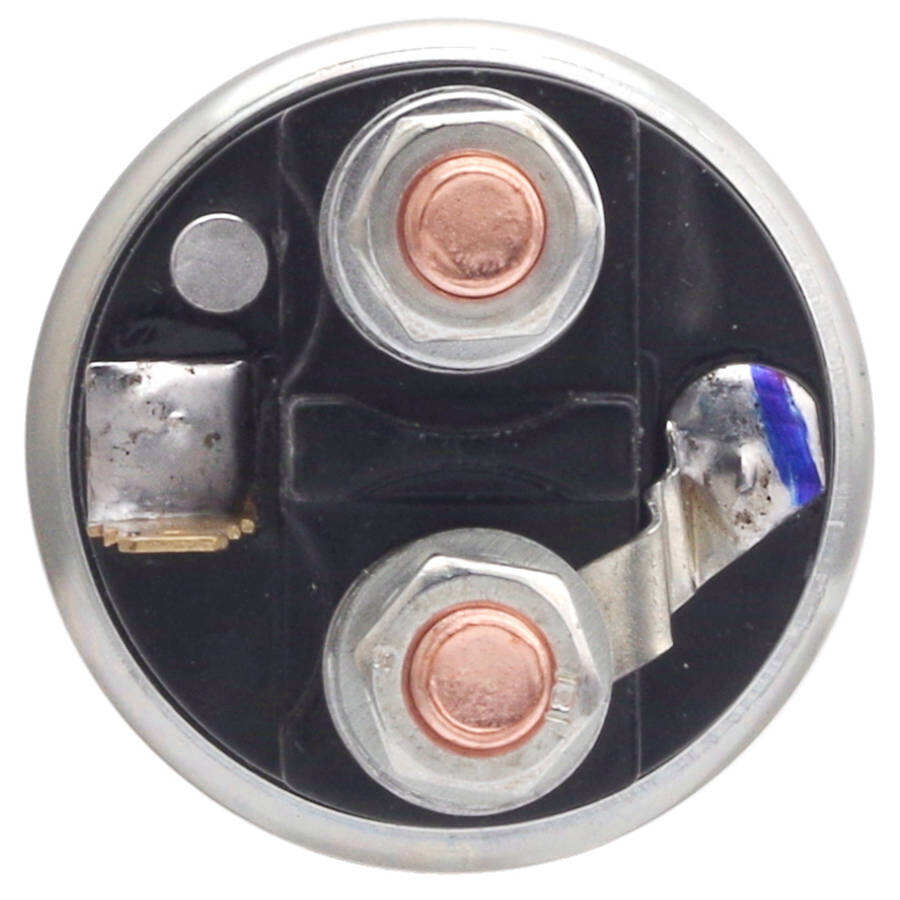

A solenoid switch in starter motor manufacturing represents a critical component that plays a pivotal role in modern automotive electrical systems. This electromagnetic device serves as the crucial link between the vehicle's ignition system and the starter motor, enabling seamless engine startup operations. Manufacturers specialize in producing high-quality solenoid switches that feature precision-engineered contacts, robust copper windings, and durable housings designed to withstand harsh automotive environments. These components are engineered to handle high current loads while maintaining reliable switching performance throughout thousands of activation cycles. The manufacturing process incorporates advanced quality control measures, including automated testing systems and rigorous durability assessments, ensuring each unit meets strict industry standards. Modern solenoid switch production facilities utilize state-of-the-art equipment for coil winding, contact assembly, and final testing, resulting in products that deliver consistent performance and long service life. The manufacturing capabilities typically span various specifications to accommodate different vehicle types, from compact cars to heavy-duty commercial vehicles, with customization options available to meet specific OEM requirements.